MosaikoLab and its new tangible logo

Tuesday, June 1st, 2010MosaikoLab is a project that still doesn’t have a specific purpose. Maybe it will never have one. But in the meanwhile, it has changed its face twice already.

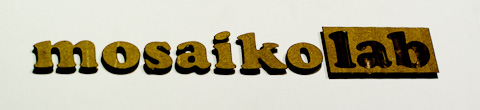

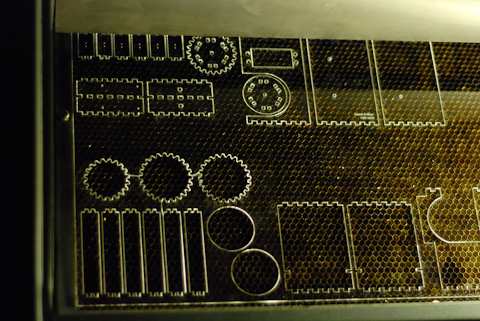

Now it becomes more Lab than ever – I used the logo to experiment with some materials and the lasercut.

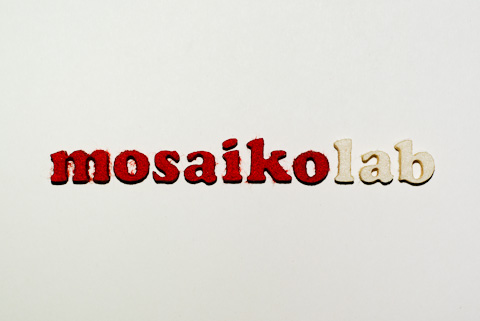

I really like the combination of cardboard and masking tape, it gives a feeling of provisory, or patch. Some months ago, making the biz cards, I accidentally cut a piece of tape with the lasercut that was meant to hold the card sheet, and it looked amazing. It creates a nice effect just leaving the fill of the typeface with tape.

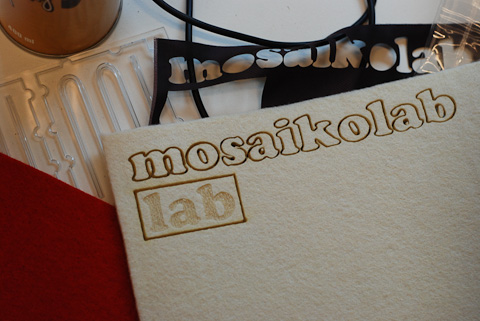

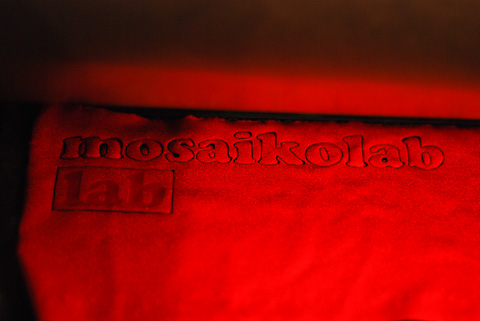

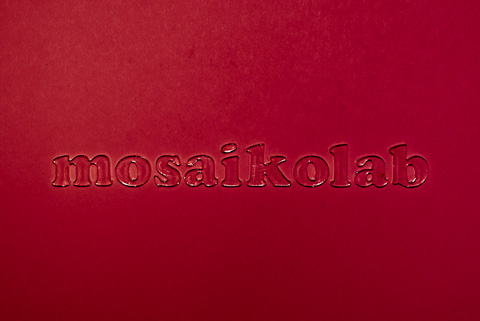

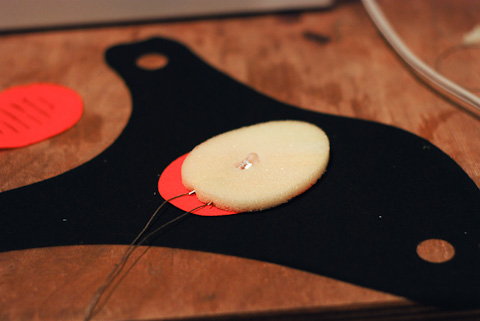

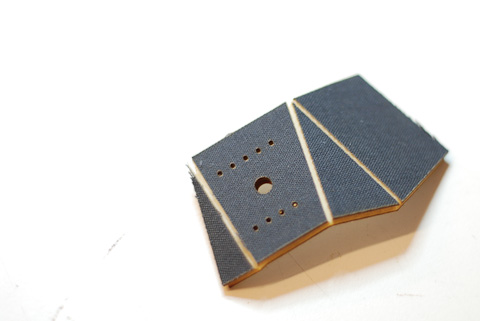

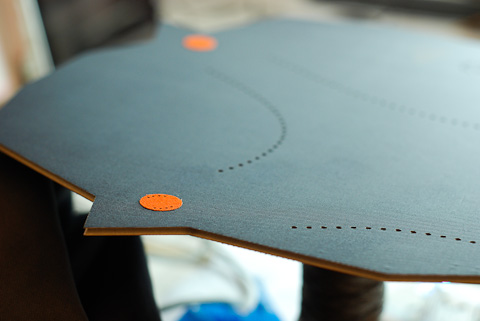

This is synthetic felt, which smells really bad when burned but looks great both cut or rastered (crispy lowered surface):

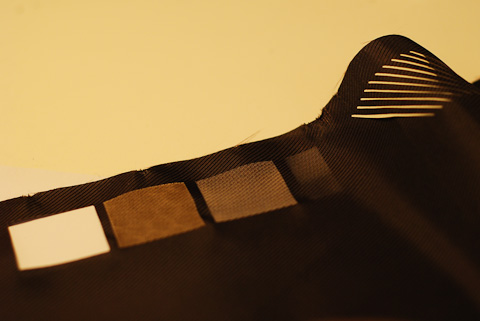

The finish with lycra is sharp, with slightly burned edges that prevent fraying:

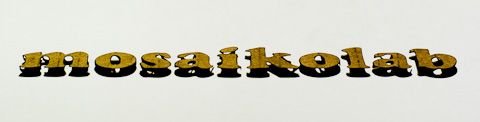

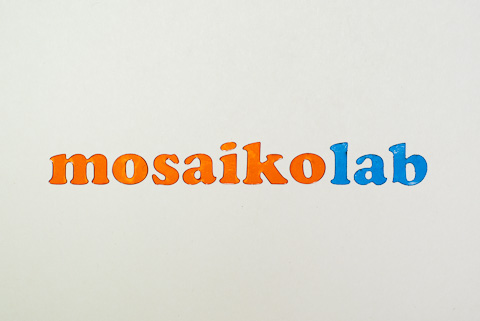

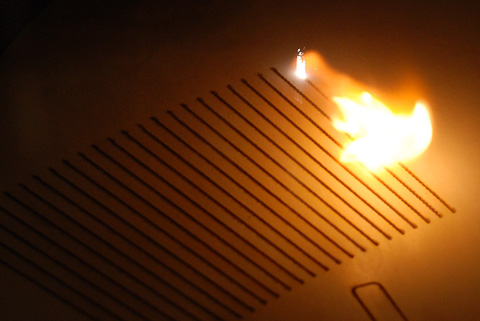

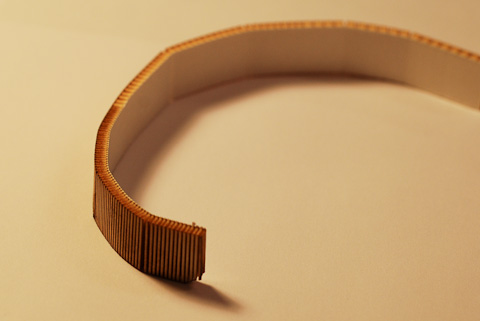

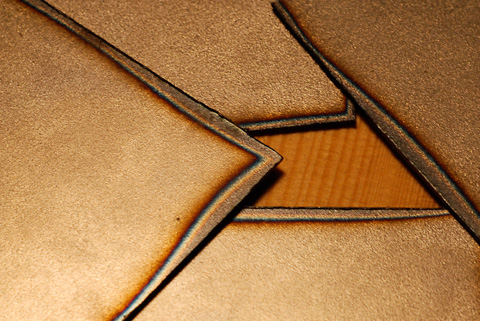

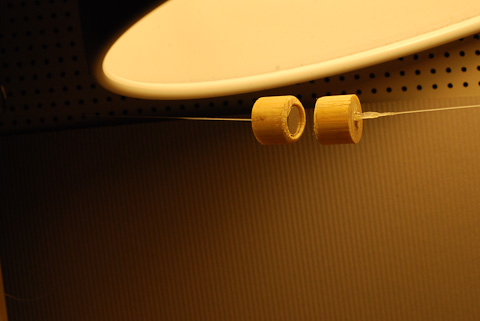

And I’m in love with corrugated cardboard. It’s really cheap (or free!), with imperfections and with multiple possibilities of changing the aspect. By rastering corrugated cardboard with the appropriate power is possible to remove only the top layer, creating visual effects with the cavities. Also it creates nice a shadow effect with oblique light.

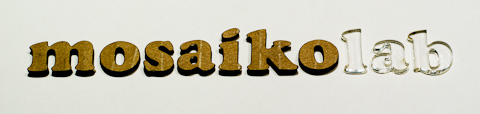

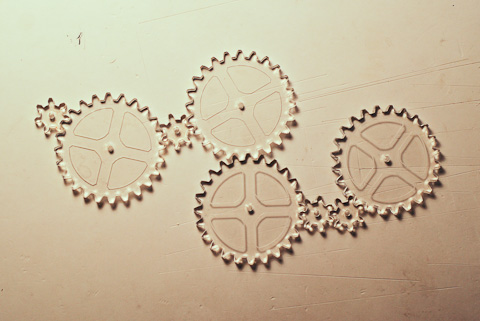

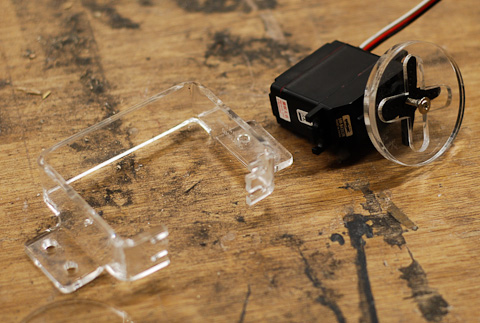

Of course I used acrylic also! :)

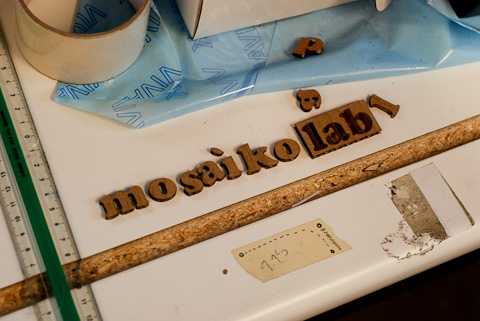

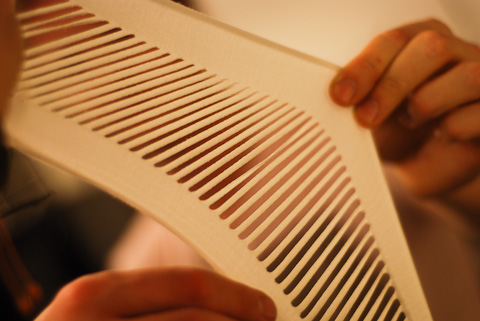

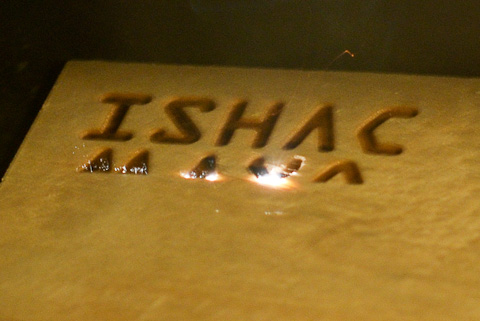

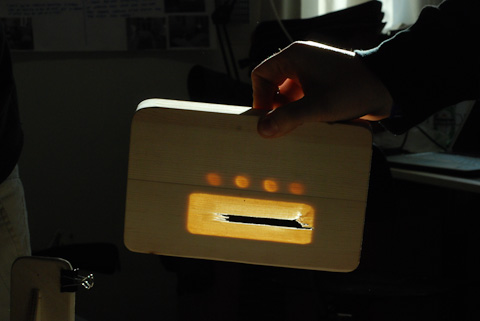

And thin plywood. The dark letters are rastered,with burnt wood smell included :)

And acetate usually used as light filters:

MosaikoLab takes shape!

More pictures here.